M J Painting has over 15 years of oil and natural gas coating experience in the upstream, midstream and downstream industries.

We perform each crucial step of the oil and natural gas energy services specific requirements for tanks and well heads to compressor stations and pipelines with corrosion prevention coating expertise. Masking, environmental containment, surface preparation, coating and final touchups can be done onsite and in-shop.

How Do We Mask & Contain?

M J Painting’s mobile spray rigs have precision tools and equipment necessary to complete each coating project phase.

Our coating crews have the experience and knowledge to prepare any surface, apply the proper coatings and provide Quality Control Documentation. All employees are safety trained and operator qualified through Veriforce and MEA (Midwest Energy Association). We offer NACE Certified Painting crews or third party resources to perform CIP Level 1 Coating Inspections.

COMPLIANCE AND MAINTENANCE

M J Painting’s compliance and maintenance services help to ensure pipeline integrity and productivity. Our certified coating crews repair oil and natural gas non-compliance issues in accordance with industry specifications.

M J Painting offers annual maintenance contracts nationwide helping prevent future corrosion. Our field teams use advanced project management software providing customers with real time data and cost-effective, efficient job completion.

All About Our Plural Component Applications

Coating Maintenance and Compliance:

- Corrosion Mitigation & Repair

- Integrity Inspections

- DOT Compliance

- PHMSA Compliance Projects

- Pipeline Recoating

- Pipeline Safety Regulations

- Corrosion Technicians

- Safety Trained & Certified Crews

- Annual Maintenance Contracts

- Plural Component Certified Crews

- Field Reporting Software with Real Time Reports

- Cost-Effective, Efficient Project Management

- Pipeline Productivity & Maximum Performance

Oil/Gas Evaluation Request

Contact us for an evaluation of your corrosion compliance issues and maintenance contracts

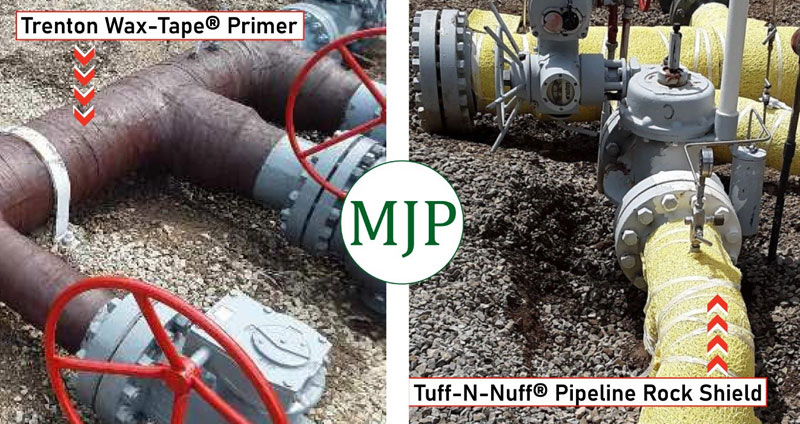

ANTICORROSION WRAP

When does oil and natural gas pipeline need anticorrosion wrap? M J Painting oil and gas coating company recommends anticorrosion wrap for air to soil transitions or to coat wet pipe. SSPC-SP2 Hand Tool Cleaning is performed when abrasive blasting is not possible or pipe location isn’t safe for heavy backhoe equipment. For SSPC-SP2 surface preparation our certified corrosion technicians use non-powered hand tools to safely remove rust, old paint and contaminates. M J Painting’s gas pipeline coating crews next apply Trenton Wax-Tape® Primer finishing with Tuff-N-Nuff® Pipeline Rock Shield to protect pipe from backfill, rocks and other impact. Service is stand alone or included with annual maintenance.

- SSPC-SP2 Hand Tool Cleaning

- Trenton Wax-Tape® Primer

- Tuff-N-Nuff® Pipeline Rock Shield

- Protect Pipe from Impact

- Safe Non-Powered Tools

- Stand-alone service or included with annual maintenance

M J Painting Contractor Corp.

TRAINING:

- Veriforce

- MEA (Midwest Energy Association)

- ITS (Industrial Training Services)

- PEC (Petroleum Education Council)

- DeFelsko testing equipment

- 40+ safety programs

- 4 gas LEL meters

CONFINED SPACE:

- Silos

- Pump stations

- Tanks

- Underground pipes

BELOW GROUND:

- Girth welds

- HDD

- Slip bores

- Air to soil transitions

- Pipeline rehabilitation projects